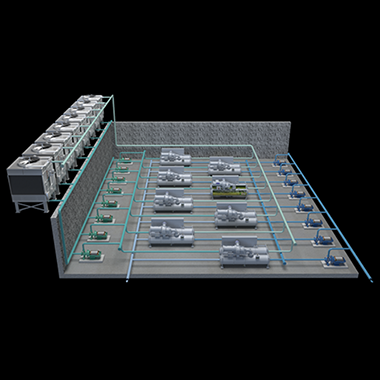

Chilled water system optimizer

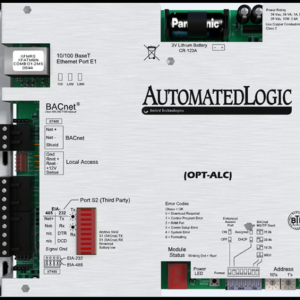

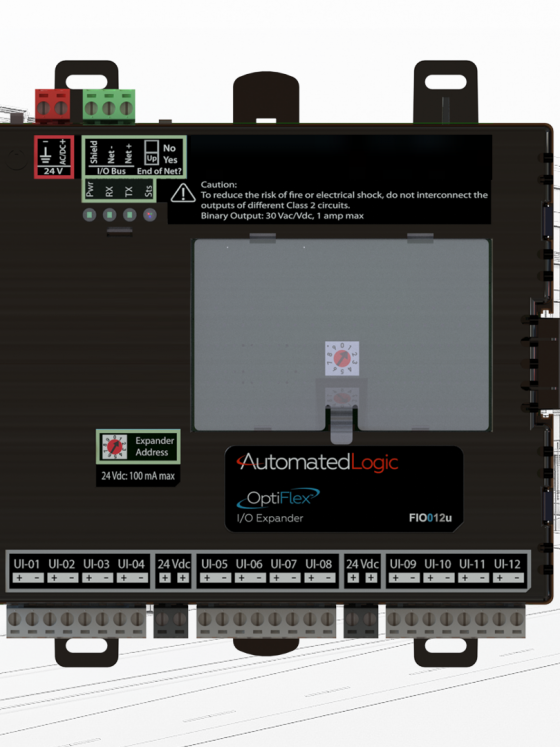

The Automated Logic® chilled water system optimizer is a sophisticated, scalable, native BACnet optimization solution for chilled water plants. The chilled water system optimizer minimizes the energy use of the entire chilled water system, up to and including air handling units and other water side chilled water consumers. By providing optimized control of the chilled water and condenser water setpoints, the chilled water system optimizer can lower energy costs while also maintaining occupant comfort levels in the building. The chilled water system optimizer solution consists of a self-adapting control algorithm packaged in an application specific Automated Logic controller.

Key Benefits:

- Intuitive – Monitors and displays optimization metrics via integrated dashboard.

- Scalable – Designed to be used on plants of varying size, up to a maximum of

- 8 chillers in parallel

- 40 chilled water primary, secondary and tertiary variable speed pumps

- 40 variable speed AHU fans serviced by system

- 20 condenser water pumps

- 20 cooling towers variable speed fans

- Flexible – Works with the chilled water side alone, condenser water side alone, or both.

- Comprehensive – Can work with virtually any existing plant control system.

- Dynamic -Adapts automatically to changing environmental conditions and system changes over time. Senses total system energy usage including all plant room equipment and airside energy consumption.

- Open – Integrates easily via network communications with all mechanical and electrical equipment, regardless of brand.

- Seamless – Interfaces easily with the Automated Logic® PlantCTRL™ chiller plant solution enabling additional plant efficiency improvements.

- Intelligent – Adjusts chilled water and condenser water setpoints to achieve overall combined chiller plant and air-side energy savings.

- Efficient – Minimizes energy use over the entire chilled water system, including chilled water plant equipment and air-side chilled water consumers. Based on field tests1, potential energy savings from 3 – 15% are possible.

- Non-disruptive – Integrates to the existing plant control system, intelligently computing optimum chilled water and condenser water setpoints while continuously monitoring plant room and load-side energy consumption. Fail-safe logic is designed into the system so that the plant will revert to default setpoints in the event that optimized setpoints cannot be determined.

- Affordable – Lower first cost versus competitor offerings that require extensive plant analysis, system modeling, control system and mechanical system upgrades.

Patent pending: US20150052919 A1/M

1 – Optimizer algorithm was evaluated using modeling and computer driven simulations and tested in several field trial sites. Actual savings may vary depending on duration of use, plant size, equipment used, and the existing plant control strategy.

Reviews

There are no reviews yet.